The main raw ingredient for fermentation is ripe fruit, which is transported via a screw conveyor into a grinder. That breaks up the fruit to make fermentation easier, but without crushing the pits. Then it is pumped into fermentation tanks where fermentation takes place.

Alcoholic fermentation is a process during which yeast transforms sugars into alcohol. This transformation of sugar into alcohol is accomplished by yeast enzymes, with byproducts of carbon dioxide and heat. The fermentation process ceases at temperatures below 10 °C and it proceeds faster at increased temperatures; however it is better to ferment slower – 15 °C is generally considered the ideal temperature, which should be maintained throughout the entire process. Alcoholic beverages created via natural fermentation contain only about 14% alcohol by volume. To attain a higher alcohol content, distillation is necessary.

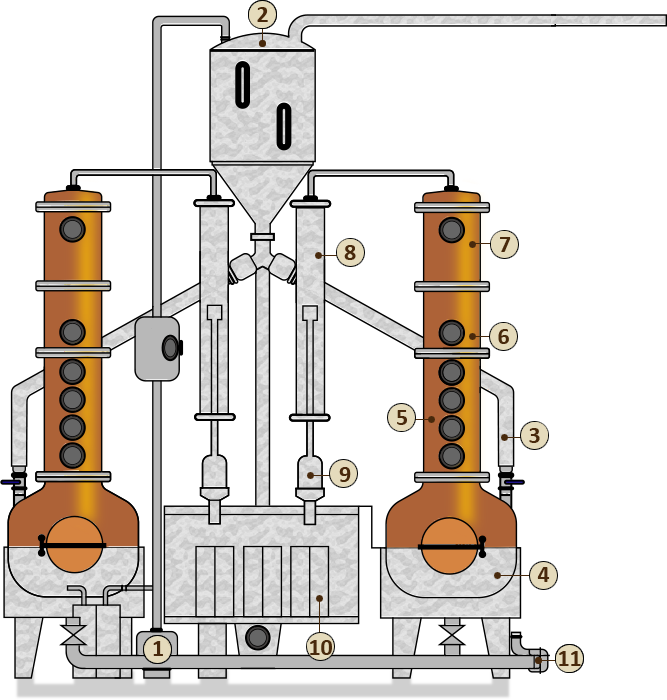

Multiple distillation yields a distillate (70–75%), which must then be diluted before bottling.

Only ripe and pure fruits come into production

Only ripe and pure fruits come into production Transport of fruits for processing

Transport of fruits for processing Screw conveyor

Screw conveyor The grinder disrupts fruits to facilitate the fermentation process

The grinder disrupts fruits to facilitate the fermentation process The Fermentation tank and the fermentation plug

The Fermentation tank and the fermentation plug

Stainless steel tanks for ageing spirits

Stainless steel tanks for ageing spirits Golden slivovitz ages in oak barrels

Golden slivovitz ages in oak barrels The capacity of the wooden barrel is about 300 l

The capacity of the wooden barrel is about 300 l Today giant vats serve as a viewing platform within the excursion route

Today giant vats serve as a viewing platform within the excursion route

Product labeling – on the line

Product labeling – on the line Labeling of the final product - manual

Labeling of the final product - manual The bottling line

The bottling line The Final product with excise stamp

The Final product with excise stamp Using the tunnel, cartons with finished products are transported to the shipping warehouse

Using the tunnel, cartons with finished products are transported to the shipping warehouse

Copyright © 2019 - RJELÍNEK. ALL RIGHTS RESERVED.